Isolation Crane

-

Home > Products > Overhead Crane > Isolation Crane >

Isolation Crane

Weihua Crane Machinery Co., Ltd.

Address:Industry Park, Changyuan, Henan, P.R.C

Email:marketing@craneus.com

Email:contact@craneus.com

Overview

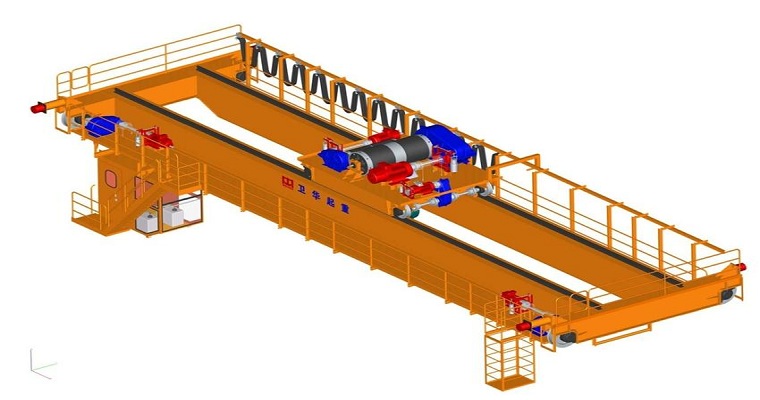

Isolation crane is designed based on double girder overhead crane; it is lifting machinery for loading and lifting goods under charged environment.

When the isolation crane works in a live environment, in order to prevent the current may be passed to the crane by hanging items, endangering the lives and safety of drivers. Therefore, set up three insulated devices in the three parts, they are in the hook and pulley, lifting mechanism and the trolley frame, trolley frame and crane.

Isolation crane is suitable for smelting aluminum, magnesium, lead, zinc and other electrolysis nonferrous metals plant, for material handling and lifting, equipment installation and maintenance. Working level is heavy duty system.

Weihua Crane is professional material handling equipment manufacturer and servicer with largest production in global. Provide you with overhead crane, gantry crane, electric hoist, etc. of safe, reliable and efficient crane solutions and services.

Features

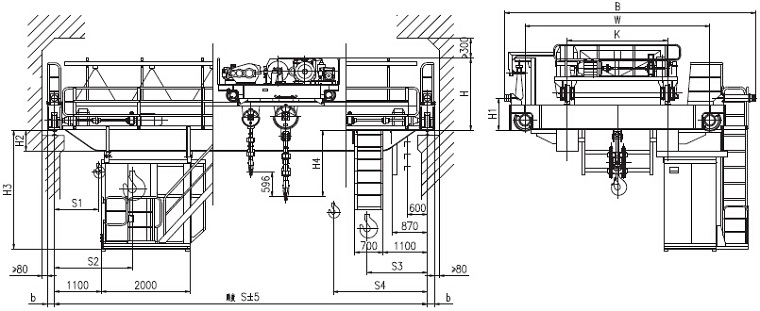

Isolation crane mainly consist of bridge, driver’s cabin, traveling mechanism, the trolley parts, electrical control system and other components. Adopt double-beam double-track and winch single trolley structure.

Isolation crane generally including three grades Insulations: Between trolley frame and crane, lifting mechanism and the trolley frame, hook and pulley. Setting up three insulated devices to meet three grades requirements. Epoxy phenolic glass cloth board has been mostly used as insulating material. (The electrician use alkali-free glass cloth impregnated with epoxy phenolic resin by hot pressing formed into laminate, with high mechanical and dielectric properties, apply to insulating structural parts for motor and electrical equipment, and can be uses in wet conditions and transformer oil). The crane is mature and reliable, easy and smooth operation, advanced technology; it is a mature product of our company is for many years.

Bridge Frame

Bridge is the main force component of isolation crane, using the structure of double-beam and double-track, take the main beams and end beams as the main force pieces, supplemented by trolley tracks, walkway, railings, ladders and other ancillary metal structures.

Main beams and end beams are box-shaped structure made of steel Q235 or Q345, minimum thickness of steel not less than 6mm. Main beam camber is (1 ~ 1.4) S / 1000, and the maximum camber position controlled within tenth of central span.

Trolley tracks lay on the bridge using one whole railway that joints welding as integration, to ensure the trolley running well. There set up insulating equipment between trolley track and trolley wheels to ensure that trolley and crane parts are insulating.

Driver’s Cabin

Driver’s cabin is workplace that operator manipulating the crane, using closed and tempered glass cabin. Its structure type design has taken into consideration not only the needs of a variety of functions: durable, safe and reliable, but also consider the good vision, comfortable and beautiful, indoor with an air conditioner, so the driver can work in good environment.

In order to ensure the operator with good vision, before the positive top, before the bottom of the side wall and rear wall of the cabin are fitted with tempered glass, driver in seat with maximum elevation from 55 ~ 60 °, the maximum angle from 70 ~ 75 °, the driver fixed maximum positive perspective is 120 °, rotating seat can up to 270 ° viewing angle of the front range.

Cabin frame are welded by rolled structural steel and stamped sheet steel, insulated rubber carpet laying on the floor surface. Inner and outer sides of the glass can be safely and easily wiped. The upper window frame and cabin frame are fixed.

Cabin also set alarms to ensure safe operation of the crane. Various settings arranged in cabin, which take full account of the driver easy maintenance and manipulation, unobstructed walking and activity space. Guaranteed under accident conditions, the driver can quickly and safely withdraw.

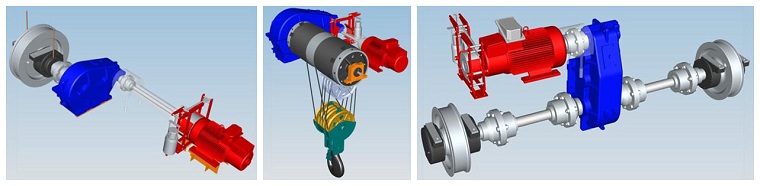

Crane Traveling Mechanism

Long traveling driving type of isolation crane: motor driving the reducer through coupling and driving shafts, gear connected with wheel shaft. When starting operation, driving wheel never slip, when braking, it is steady and reliable. This structural arrangement is conducive to all the parts installation, maintenance and removal of driving system.

Generally crane insulated cannot be done on the wheels, because of the need of the bridge frame to be as the ground wire.

Trolley Parts

Main and auxiliary hoisting mechanism of isolation crane arranged in the same trolley rack, each set up with separate driving device, main and auxiliary lifting mechanism not only can finish the lifting and handling independently, but also can be coordinated to complete the work of turning over object.

Hoisting mechanism operating principle: Motor acting through the gear shifting speed, and then driving drum through drum coupling, finish hook hoisting through wire rope winding system. Between lifting hook and pulley block, hoisting mechanism and trolley frame, both set up with insulating device, each agency including motor, reducer and pulley block set up with insulation plate. Hoisting mechanism uses dual braking.

Isolation crane trolley traveling mechanism and crane traveling mechanism adopt the same driving type.

Insulation Crane Electrical Control System

Isolation crane electrical operation control unit installed in the cabin, the other electrical components are generally installed on walkway stage or in electrical room. Motors, brakes and cables are anti-corrosion type, resistors using stainless steel, other electrical components are sealed and anti-corrosion.

Isolation crane power supply including three types: angle slide wire, safety slide wire and cable.

Angle slide wire: Mainly used for places with large total motor power, high-temperature, dusty and such bad environments;

Safety slide wire: It is the most widely used type currently; it is safe, beautiful and easy installation;

Cable type: it is mainly used for explosion-proof crane and can also be used for a variety of small and medium sized cranes. Trolley power supply is soft cable type, to avoid maintenance personnel electric shock risk, ensuring the personal safety.

Isolation Crane Safety Protection Device

Crane main hook with overload limiter, it has functions with weight display, overload alarm and automatic power off.

Each mechanism using normally closed electro-hydraulic brake, main lifting adopt dual brakes, safe and reliable.

In addition to overload limiter and braking device, the hoisting mechanism also installed with lifting limit switch, trolley traveling and crane traveling are both equipped with limit switches, the circuit provided with overcurrent protection, no-voltage protection, phase protection, zero protection, emergency switch, the main isolating switch, hatch door interlock switch, bells prompt and other safety devices to ensure the normal operation of cranes and related personnel personal safety. Isolation crane can be equipped with a few shock proof lamps under the bridge frame according to your needs; it is good for lifting operations.

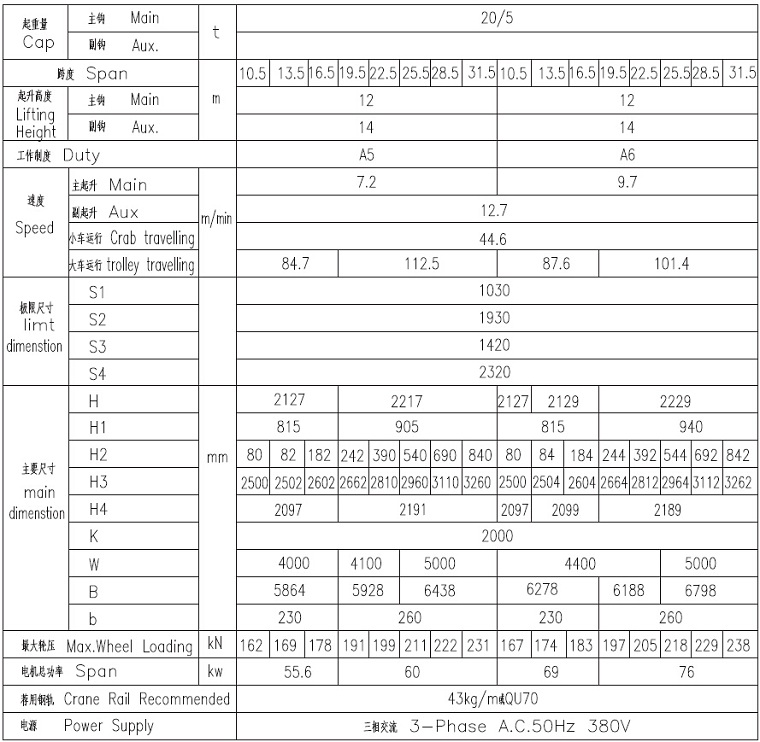

Technical Data

Contact Us

Simply complete the form below, click submit, you will get the price list and wo will contact you within one business day. Please also feel free to contact us by email or phone.

Recommend

Contact Us

Industry Park, Changyuan, Henan, P.R.C

marketing@craneus.com

marketing@craneus.com contact@craneus.com

contact@craneus.com- Tel:(0086) 15836006986

- Fax:(0086) 373 8883166

- Skype:wei.crane