How to Manage Reducer Oil LeakageⅡ

How to Manage Reducer Oil LeakageⅡ

4. Improve seal structure

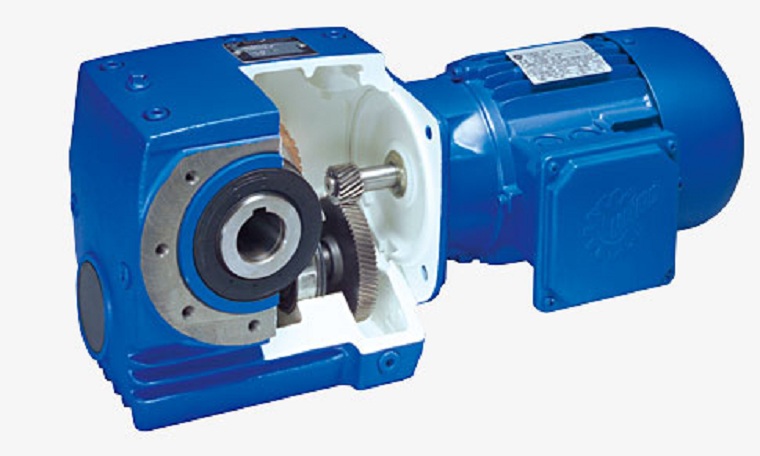

1) Output shaft for half shaft reducer seal improvements: Belt-type conveyer, spiral unloading machine, impeller coal feeder and other equipment reducer with half shaft, which is convenient to make modification. To make disintegration of the reducer, remove the coupling, remove the gear shaft seal cover, according to the supporting skeleton oil seal size, outside of the original end cover lathed tank mounted skeleton oil seal, with the spring side inward. When loaded back, if end cap away from the inside of the coupling end 35mm or more, you can install spare oil seal on the shaft outside the end cover, once the oil seals fail, you can remove the damaged seal, and push the secondary oil seal into the end cap, thereby save the disintegration of reducer, removal of couplings and other time consuming processes.

2) Output shaft for the entire shaft reducer seal improvements: the whole shaft drive gear output shaft without couplings, according to 3.1 program improvement, the heavy workload is not realistic. To reduce the workload, simplify the installation process, there designed split end cover, and attempt the open type oil seal. Lathed tank outside the spilt end cover, remove the spring before loaded oil seal, amputate the oil seal to opening shaped, set the oil seal on the shaft from the opening, the opening butted with adhesives, with the opening side up, and then loaded spring, pushed end cap into it.

5. Earnestly implementing repair technology

During reducer repair, the technological procedure should be earnestly implemented, oil seal cannot be installed backwards, not to damage oil seal lip, no deformation of the outer edge, the spring cannot come off, the combined surface to be cleaned, sealants applied evenly, and the amount of fuel cannot exceed the oil gauge scale.

6. Wiping

Through managing of the reducer static sealing point, it is usually can achieve no leakage, but due to seals aging, poor quality, improper assembly, higher roughness of the shaft surface and related reasons that makes some dynamic seal points still with small leakage, due to poor working environment, coal dust stick to the shaft, it appears greasy and oily, so you need to wipe grease from the shaft after stop running the device.

Weihua Crane is professional material handling equipment manufacturer and servicer with largest production in global. Provide you with overhead crane, gantry crane, electric hoist, etc. of safe, reliable and efficient crane solutions and services.

Contact Us

Simply complete the form below, click submit, you will get the price list and wo will contact you within one business day. Please also feel free to contact us by email or phone.

Recommend

Contact Us

Industry Park, Changyuan, Henan, P.R.C

marketing@craneus.com

marketing@craneus.com contact@craneus.com

contact@craneus.com- Tel:(0086) 15836006986

- Fax:(0086) 373 8883166

- Skype:wei.crane